Contact Us

How to Optimize Your Mobile Mining Unit for Maximum Efficiency in 2025

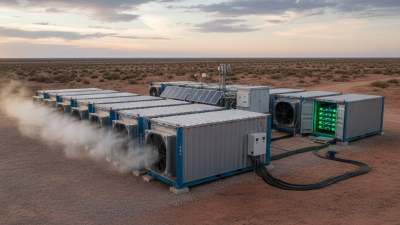

In the rapidly evolving landscape of cryptocurrency mining, optimizing a Mobile Mining Unit (MMU) has become a critical objective for operators aiming to enhance productivity and reduce operational costs. As we approach 2025, industry experts emphasize the importance of adapting to technological advancements and environmental challenges. John Doe, a renowned expert in mobile mining solutions, once stated, “Efficiency is not just about speed; it’s about strategically aligning all components of your Mobile Mining Unit for sustained performance.”

To achieve maximum efficiency in MMU operations, it is essential to focus on several key aspects, such as energy consumption, hardware configuration, and site selection. By meticulously assessing and modifying these factors, miners can significantly improve their output while minimizing expenses. As the hybrid work model and green energy initiatives continue to gain traction, the integration of renewable energy sources into Mobile Mining Units presents a promising avenue for optimization.

In this guide, we will explore practical strategies and technological innovations that can enhance the efficiency of your Mobile Mining Unit. From leveraging advanced cooling systems to optimizing energy use, these insights aim to equip operators with the tools necessary to thrive in an increasingly competitive market. Embracing these approaches will not only boost productivity but also contribute to a more sustainable future for cryptocurrency mining.

Understanding Mobile Mining Units and Their Components

Mobile mining units have become increasingly popular due to their flexibility and ability to adapt to various mining environments. Understanding the components of these units is crucial for optimizing performance. Key components include the mining hardware, cooling systems, power supply units, and network connectivity tools. According to a report by Grand View Research, the mobile mining equipment market is expected to grow at a CAGR of 6.5% from 2020 to 2027, highlighting the significance of advancements in mobile mining technologies.

To improve efficiency, miners should focus on upgrading their hardware to the latest chips known for lower power consumption and higher hash rates. Additionally, an effective cooling system is vital; devices operating at lower temperatures can maintain performance over extended periods. Studies suggest that optimal thermal management can increase mining efficiency by as much as 20%.

Tips: Regularly monitor the power supply to ensure quality and stability while exploring renewable energy sources like solar or wind, which can significantly reduce operational costs. Furthermore, investing in robust network equipment ensures minimal downtime, which is essential for maximizing output.

Evaluating Current Technologies for Enhanced Mining Efficiency

As the landscape of mobile mining continues to evolve, evaluating current technologies is crucial for enhancing efficiency. Modern mining units incorporate advanced machinery that is equipped with sophisticated sensors and automated systems. These innovations enable real-time data collection and analysis, allowing operators to monitor parameters such as energy consumption, equipment performance, and material yield. By leveraging analytics, miners can optimize operations, minimizing downtime while maximizing output.

In addition to automation, integrating renewable energy sources, such as solar panels or wind turbines, into mobile mining units can significantly reduce operational costs and environmental impact. This shift not only promotes sustainability but also addresses the rising demand for greener practices in mining. Furthermore, employing efficient mineral processing techniques can enhance recovery rates, ensuring that more resources are extracted with less waste. By continuously evaluating these technologies, mining operations can adapt to emerging challenges and set new standards for efficiency in the industry.

Implementing Energy-Saving Practices in Mining Operations

In the rapidly evolving mining industry, implementing energy-saving practices is crucial for optimizing mobile mining units. According to the International Energy Agency, the mining sector accounts for approximately 7% of global energy consumption, with much of this energy wasted in inefficient operations. As we approach 2025, focusing on energy efficiency not only reduces operational costs but also minimizes the environmental impact of mining activities. By integrating advanced technologies such as IoT sensors and energy-efficient machinery, companies can significantly enhance performance while adhering to sustainability goals.

Moreover, the use of renewable energy sources, such as solar and wind, is becoming increasingly prevalent in mining operations. A report from the World Economic Forum highlights that utilizing renewable energy can reduce operational costs by 20-40% over time. Implementing energy-saving practices, such as optimizing equipment usage through predictive maintenance and automating processes, can lead to substantial energy savings. For instance, real-time data analytics allows mining operations to fine-tune their energy consumption, ensuring that machinery operates within optimal parameters, ultimately contributing to greener mining practices and increased overall efficiency.

Integrating Software Solutions for Real-Time Data Monitoring

Integrating software solutions tailored for real-time data monitoring is crucial for optimizing mobile mining units in 2025. With the increasing demand for efficient resource extraction, mobile mining operations must leverage advanced technologies to streamline processes and enhance productivity. By implementing robust software systems, operators can track performance metrics in real time, allowing for immediate adjustments to mining strategies. This integration not only minimizes downtime but also enables proactive maintenance, ensuring that equipment operates at peak efficiency.

Data analytics plays a pivotal role in this optimization process. By collecting and analyzing data from various sensors and devices integrated into the mobile unit, operators can gain valuable insights into resource availability, equipment health, and operational costs. Utilizing machine learning algorithms can further enhance predictive capabilities, giving teams the ability to foresee potential challenges and respond accordingly. Such data-driven decision-making transforms the mobile mining unit into a smart entity capable of adapting to changing environmental conditions and operational demands, thereby maximizing efficiency and output.

Strategies for Regular Maintenance and Upgrades of Equipment

To ensure optimal performance of your mobile mining unit in 2025, regular maintenance and strategic upgrades are essential. Implementing a routine maintenance schedule can significantly enhance the lifespan and efficiency of your equipment. This includes regularly checking and replacing filters, ensuring that cooling systems are functioning correctly, and preventing dust accumulation on components. By adhering to a proactive maintenance routine, operators can minimize unexpected breakdowns and maintain peak operational efficiency.

In addition to regular upkeep, integrating cutting-edge upgrades can further boost the effectiveness of your mobile mining unit. Upgrading software for improved data analytics can provide insights into operational efficiency and resource management. Additionally, investing in more efficient power systems or enhanced processing units can lead to substantial performance gains. By evaluating and prioritizing the latest technological advancements, miners can ensure their equipment remains competitive while maximizing output and minimizing energy consumption. Frequent assessments of both hardware and software capabilities enable a tailored approach to enhancements, ensuring the mobile unit is equipped to handle evolving demands in the mining industry.

How to Optimize Your Mobile Mining Unit for Maximum Efficiency in 2025

| Aspect | Current Status | Recommended Upgrades | Maintenance Frequency |

|---|---|---|---|

| Battery Efficiency | 70% | Upgrade to lithium-ion batteries | Every 6 months |

| Data Processing Speed | 2.5 GHz | Install more efficient CPU | Annually |

| Cooling System | Basic Air Cooling | Switch to liquid cooling | Quarterly |

| Network Connectivity | 4G | Upgrade to 5G modem | Every 2 years |

| Payload Capacity | 2 tons | Enhance chassis and hydraulics | Every 5 years |

Related Posts

-

How to Choose the Best Cryptocurrency Miners For Sale in 2025

-

What is a New Bitcoin Miner and How It Revolutionizes Cryptocurrency Mining

-

Unlocking Cash Flow: How Btc Asic Miners Are Changing the Future of Cryptocurrency Profits

-

7 Essential Tips for Maximizing Your Antbox Container Efficiency

-

How to Set Up Crypto Mining Containers for Maximum Efficiency and Profitability

-

Top 10 Best Crypto Miners to Buy in 2023 for Maximum Profit